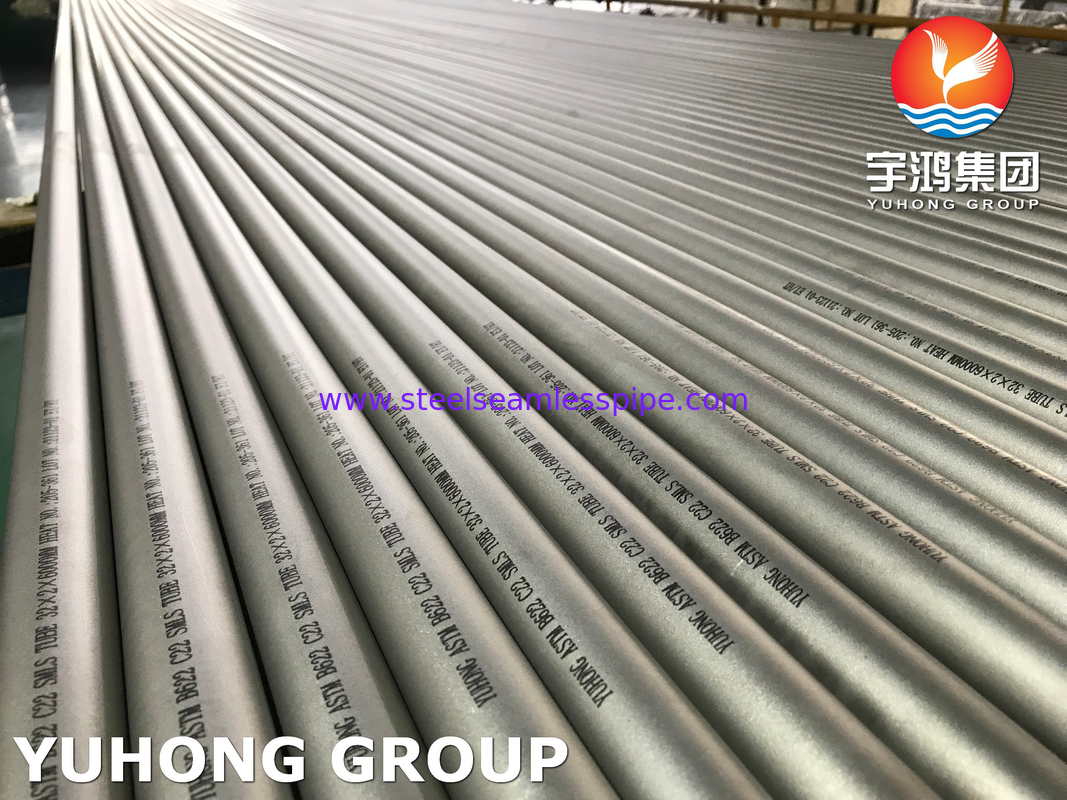

شركة Yuhong Holding Group Co، LTD

اترك رسالة

يجب أن تكون رسالتك بين 20-3000 حرف!

يجب أن تكون رسالتك بين 20-3000 حرف!

من فضلك تفقد بريدك الالكتروني!

من فضلك تفقد بريدك الالكتروني!

إرسال

مزيد من المعلومات يسهل التواصل بشكل أفضل.

السّيد

- السّيد

- السيدة

حسنا

تم الإرسال بنجاح!

حسنا

اترك رسالة

يجب أن تكون رسالتك بين 20-3000 حرف!

يجب أن تكون رسالتك بين 20-3000 حرف!

من فضلك تفقد بريدك الالكتروني!

من فضلك تفقد بريدك الالكتروني!

إرسال